Triaxial Geophone

Smart Geophone Sensor from Soft dB

Measure vibration levels caused by blasting, microseismicity, pile-driving and other activities with precision, in the construction and mining sectors, thanks to our intelligent triaxial geophones.

Capture valid, reliable, and accurate data and benefit from simplified maintenance and calibration with the sensor's built-in intelligence and digital signal processor.

An essential geophone that provides superior quality, impressive pricing, and advanced features.

Ask for priceSee technical documentation

Measure Vibratory Impacts with Superior Accuracy, Without the Risk of High-Frequency Saturation

Microseismicity

Blasting

Demolition

Tunnel and Excavation

Pile-driving

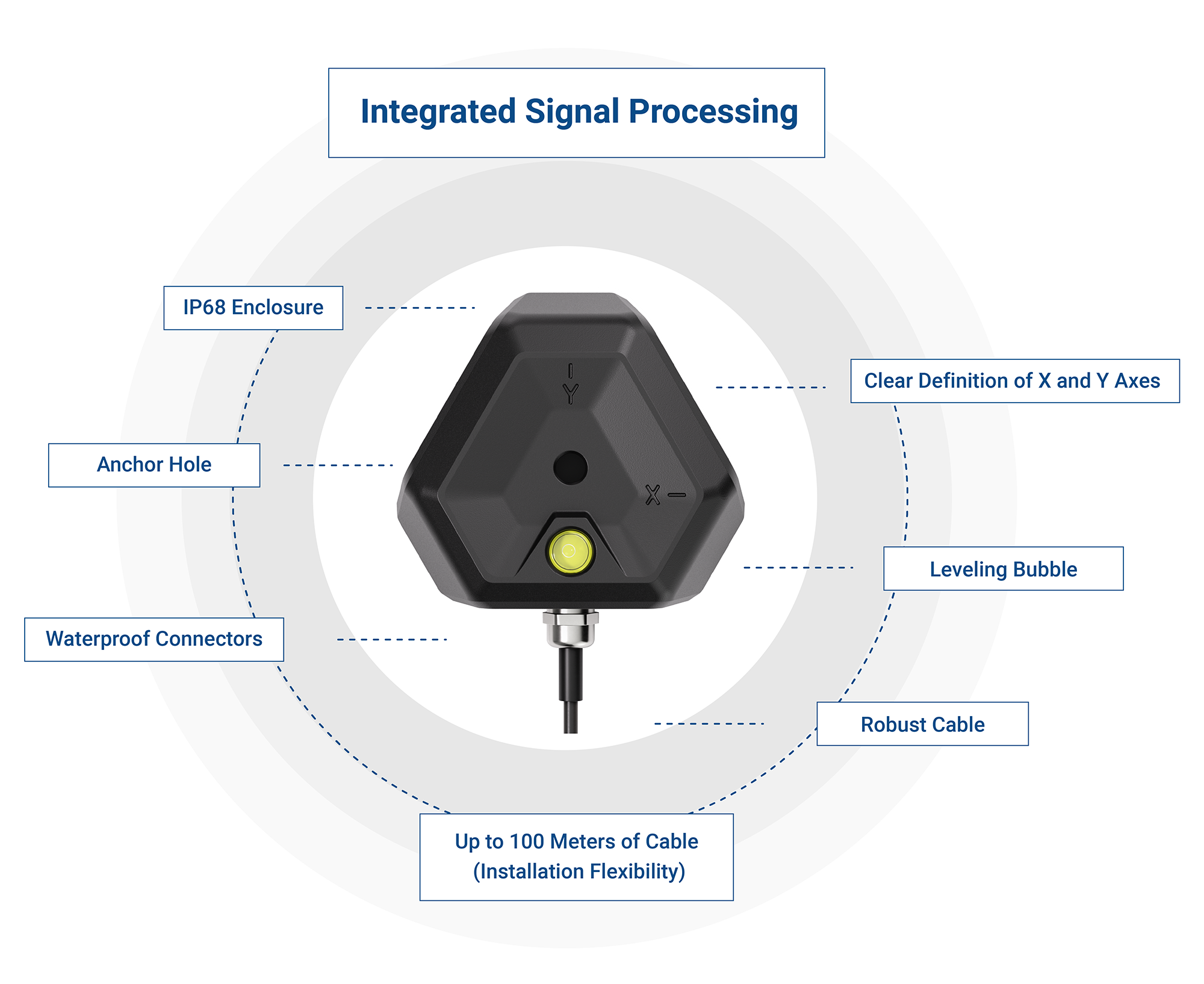

Key Features of our Smart Triaxial Geophone

Automatic Sensor Check

- Built-in intelligence automatically checks the sensor to ensure optimal operation.

Simplified Maintenance and Calibration

- Only the sensor needs to be sent to the laboratory for calibration. Simple, practical, and efficient.

Flexible Alarm System for Threshold Violations

- Alarms are adjustable to your project's specific frequency criteria.

Wide Dynamic Data Range

- Ability to measure very low vibration levels from one micrometer per second.

Vibration Data per Second on Request

- Ideal component for measuring human comfort and sensitive equipment.

Superior Signal Quality

- No data interference.

Wide Measurement Range

- RMS value.

- Peak particle velocity (PPV, PVS).

- Continuous time signal.

- 1/3-octave spectrum (0.5 to 400 Hz).

- FFT (Pro Stations).

4 Models for a Wide Range of Applications

- ISEE / AS 2187.2 (2-250 Hz, 120 mm/s).

- DIN (1-80 Hz, 120 mm/s).

- HS1 (5-100 Hz, 12 mm/s).

- HS2 (10-200 Hz, 12 mm/s).

Designed for Extreme Conditions

- IP68 protection rating.

- Operating temperature: -40ºC to +50ºC.

- Highly robust cable.

- Sensor ideal for construction sites and open-pit mining.

Perfect for Ensuring the Integrity of Structures, Sensitive Equipment, and Human Comfort

Soft dB's Smart Geophone Sensor is ideal for detecting microearthquakes and measuring vibrations caused by explosives, blasting, hydraulic hammers, etc., often used on construction and mining sites.

Its exceptional signal quality enables detection of vibrations as low as one micrometer per second, with no risk of high-frequency saturation.

This triaxial geophone is perfect for monitoring vibrations near sources of impact, such as a jackhammer close to a wall.

Our geophone sensor superior capabilities ensure the integrity of structures, buildings, and infrastructures adjacent to the worksite, protects vibration-sensitive equipment, and maintains the comfort of residents in neighbouring communities of the site.

Simplified Maintenance and Installation

Save time and money.

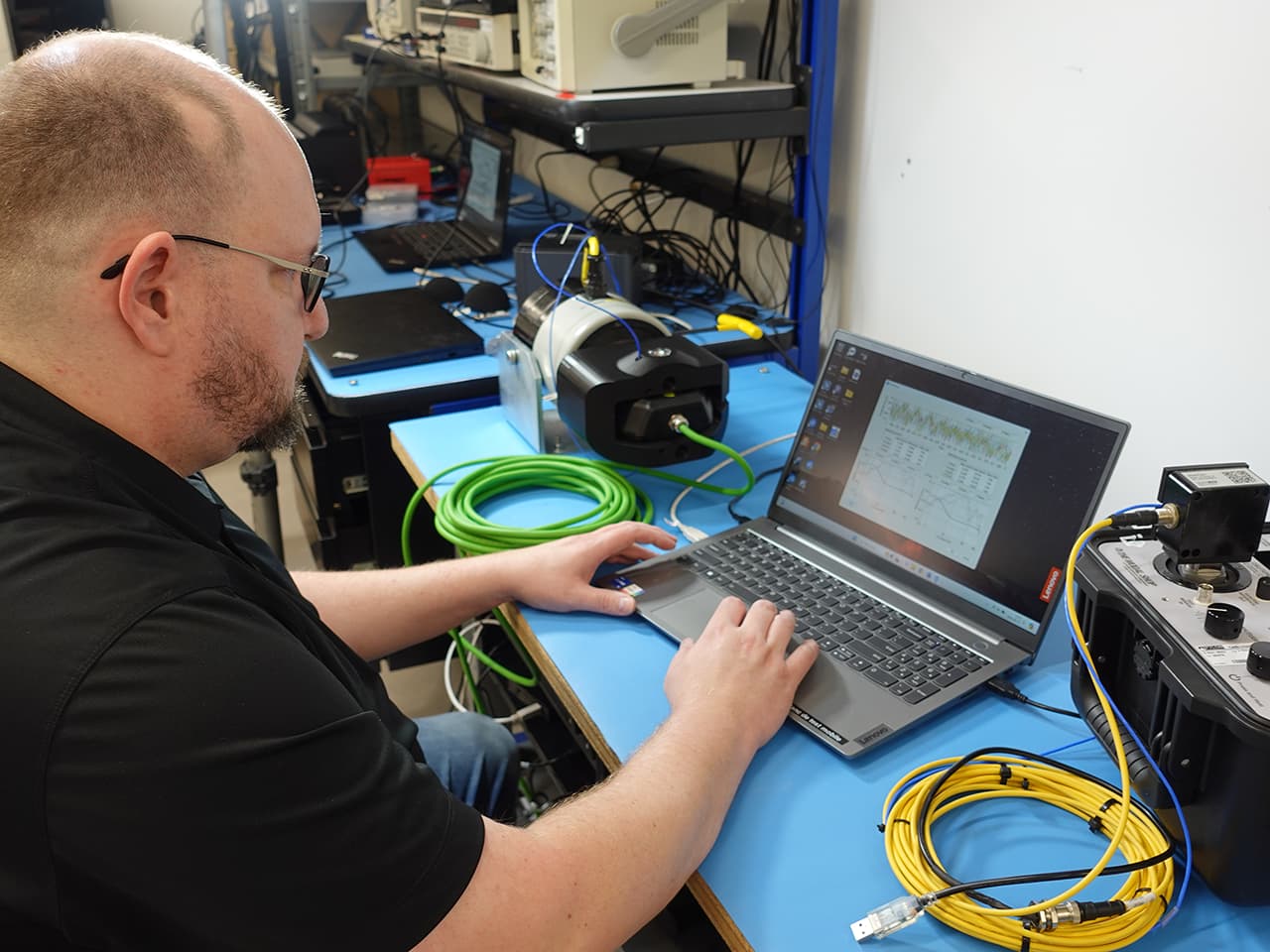

Our signal acquisition and processing system is integrated directly into the geophone. Therefore, you will only need to send the geophone to the laboratory when calibration and certification is required.

This allows you to avoid having to ship the complete monitoring station (incurring unnecessary costs), as well as having to compensate additional stations in the field, as to not disrupt continuous monitoring.

Our triaxial geophones are also interchangeable with all Soft dB monitoring stations, so you can simply use another geophone in the field during calibration.

What's more, no reconfiguration is required when your vibration sensor returns to the field after annual maintenance, considerably reducing your risk of error. Everything is entirely automated, ensuring continuity in the quality of measured information.

One of the Most Powerful, Customizable, Alert and Reporting Systems Available on the Market

Be informed only when relevant to you.

Our alarm system is flexible in capturing threshold exceedances and can be adjusted based on your specific project criteria.

For example, alarms can be programmed for both peak and RMS speeds, and even for accelerations, as required.

This allows you to be informed only when an action is required on your part.

Automatic Sensor Check

No more questions about data quality. Get consistently reliable measurements.

Every day, each sensor performs an automatic check to ensuring optimal functionality and validity of the data being supplied.

Not only are these results recorded, they can be accessed at any time via our Soft dB Web monitoring platform.

Should a sensor detect a deviation in functionality, an automated alert is sent to you.

Valid, High-Quality, and Interference-Free Data

The vibration data that you receive is exactly what has been measured. No contamination.

Our triaxial geophones incorporate intelligent technology that processes the signal directly within the sensor, considerably reducing the risk of interference, thereby ensuring valid, accurate, and reliable data.

Soft dB's triaxial geophones allow you to measure vibration data with cables of up to 100 meters, with no loss of signal, giving you the flexibility to find the best location for communication and measurement of your most critical points.

Your One-Stop-Shop for Vibration and Acoustics. Access Turnkey Solutions, High-Performance Technologies, and Superior Expertise.

Benefit from many exclusive advantages, and compatibility of our vibration sensors with our Soft dB technologies and monitoring systems, renowned worldwide for their high quality, reliability, and comprehensiveness.

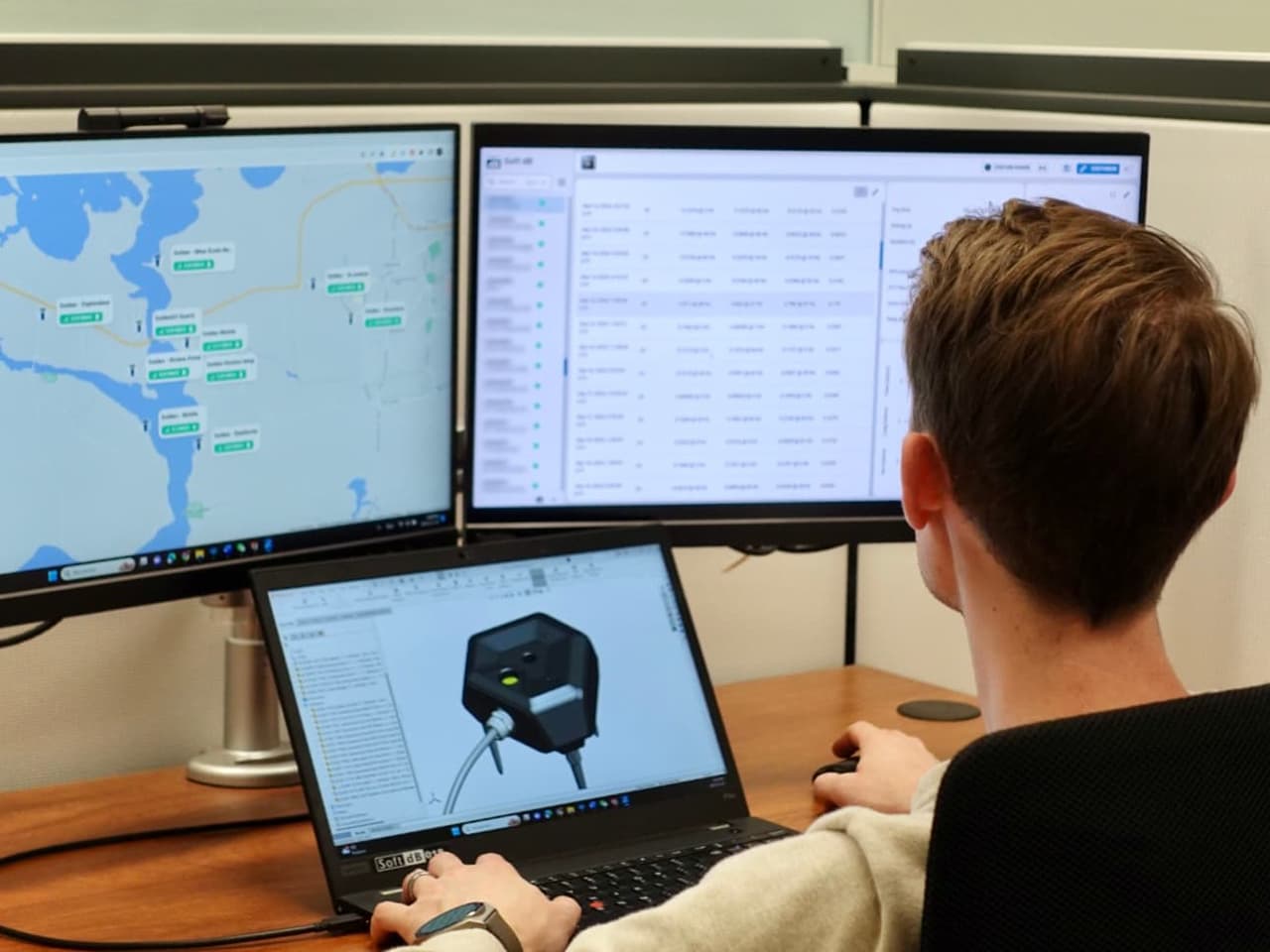

Soft dB Web Monitoring Platform: The Most Advanced on the Market

No matter what type of Soft dB sensor you require, our monitoring solution integrates all measured data, reports, alerts and more on a single Web platform.

Extremely powerful and intuitive for visualizing and processing all of your vibration and sound data, in real-time, remotely, and entirely accessible in a single location.

Master Trigger™: Automatically Receive Your Summary Reports After Blasting and Other Seismic Events

Our intelligent vibration sensors are compatible with our patented blast monitoring Master Trigger™ system, automatically generating summary reports of vibration levels measured at stations, when a certain threshold is exceeded and only when the detected event is identified as seismic or vibratory.

Benefit from the Comprehensive Expertise in Vibration and Acoustics, from Consulting to Implementation

With nearly 30 years of experience, averaging over a thousand projects each year – in the mining, construction, and heavy industrial sectors – it is highly likely that our experts have already solved vibration issues similar to yours. Take advantage of their knowledge and expertise.

- Advice on selecting the best sensors for your specific project.

- Analysis of vibration and sound data.

- Assessment of compliance with vibration and noise standards.

- Advice on the location and configuration of your vibration and/or acoustic monitoring system(s).

- Assessing the audibility of your operations.

- Participation in citizens' meetings.

- Vibration and noise management plan.

- Maintenance and calibration.

Technical Documentation

Comparison of our 4 Smart Triaxial Geophone models: ISEE & AS 2187.2 | DIN | HS1 | HS2

| Dynamic Range | ISEE & AS 2187.2 | DIN | HS1 | HS2 |

|---|---|---|---|---|

| Lower Frequency Limit, Fu (Hz) | 2 | 1 | 5 | 10 |

| Upper Frequency Limit, Fo (Hz) | 250 | 80 | 100 | 200 |

| Axis Peak Maximum Velocity (mm/s)* | 120 | 120 | 12 | 12 |

| Axis Peak Maximum Displacement (mm)* | 0.75 | 1.5 | 1.5 | 0.75 |

| Axis Peak Detection Limit (um/s)* | 45 | 30 | 1.2 | 1.2 |

| V-Sum Peak Detection Limit (um/s)* | 75 | 50 | 2.0 | 2.0 |

| Axis RMS Velocity Noise (um/s)* | 15 | 10 | 0.40 | 0.40 |

| V-Sum RMS Velocity Noise (um/s)* | 25 | 15 | 0.65 | 0.65 |

| Available KBFt | No | Yes | No | No |

| Standard | ISEE / AS 2187.2 | DIN 45669 | DIN 45669** | DIN 45669** |

* Values in the above table are minimum specifications. Typical peak maximum velocity is higher and typical vibration noise levels are lower.

** Tested according to DIN 45669 procedure and tolerances but bandwidth differs from the standard 1-80 Hz.

→ See the "Frequency Response" graphs for each model in the spec sheet

Recommended Accessories

- Calibration certificate for SGS (included)

- 3x 73 mm (2 7/8”) M10 spikes (incuded)

- Robust M12 cable, can be daisy-chained up to 100 meters

- Solid aluminium wall-mount bracket

Why Choose a Smart Vibration Sensor That Is INDEPENDENT of a Station?

In order to meet certain certifications and compliance requirements, the vibration sensor and its data processing system, which converts signals into digital data, must be regularly calibrated together.

This means that if your signal processing system is integrated into a monitoring station, you will need to send both the vibration sensor and its associated monitoring station (known as "paired"), to the laboratory. Each year, you will need to:

- Disconnect each station from the network and install a replacement, that will be used while the original is sent to be calibrated.

- Purchase additional stations (as replacements) to compensate for those being calibrated.

- Purchase additional vibration sensors (as replacements) to replace those being calibrated.

- Reconfigure your system. Each sensor is designed to work with a specific station to which it is paired. It should be noted that reconfiguration significantly increasing the risk of errors in the continuity of the measured data.

This process quickly becomes complex and very time-consuming, especially when managing a large fleet of monitoring stations.

|

With Soft dB’s vision of simplicity in mind, our R&D team developed intelligent vibration sensors, specifically designed to meet the practical realities of the field, while maintaining high quality tools for professionals. |

With our signal processing system integrated directly into the SGS triaxial geophone, the full station is not required for calibration - only the vibration sensor. During its calibration, you can simply connect another intelligent geophone, compatible with any Soft dB monitoring station, and you’re done. Simple.

Costs are dramatically reduced by avoiding the purchase of additional stations, as replacements to cover those in calibration, and you save a considerable amount of time. In addition, reprogramming the station after the sensor's calibration is not required.

Your annual calibration process becomes significantly simpler, quicker, and efficient.

How Does a Triaxial Geophone Like Soft dB’s Smart Geophone Sensor Work?

A triaxial geophone is equipped with three sensors, each oriented along the X, Y, Z axes for complete and precise measurement of ground vibrations. It is ideal for measuring very high vibration velocities, often generated by impact equipment used on construction sites, such as hydraulic hammers.

Here are the operating steps for our smart triaxial geophone:

1. When vibration waves generated by rapid impacts pass through the ground, the triaxial geophone detects movements in each direction (X, Y, Z).

2. Once captured, these vibration waves are processed directly inside the sensor and converted into a digital signal. Unlike analog signals, the digital signal is not subject to electrical voltage variations caused by magnetic fields along a cable, for example, ensuring high-quality, accurate and reliable data, free from interference.

3. The digital signal then travels in a cable up to 100 meters long, with no risk of data contamination, giving you the flexibility to have a wider range of measuring critical points.

4. The digital signal is routed from the cable to our seismographs, also known as Soft dB monitoring stations. It is then sent it to our secure Cloud server, which communicates directly with our Monitoring Web platform.

5. Via the Monitoring Web platform, you can view all your vibration and acoustic data, in real-time, set alarms, receive automated reports, and much more.

It should be noted that triaxial geophones are rarely able to measure the strong ground motion often associated with major seismic events, such as earthquakes. The risk of triaxial geophone saturation is high. For these situations, other smart vibration sensors, such as Soft dB's SVS, is an essential option to consider.

Geophones and Mems Are Available from Soft dB

For many projects, it's common to require the use of both MEMS (to measure high seismicity) and geophones (to detect microseismicity). However, they are often provided by different suppliers. This typically involves managing different web platforms to monitor your vibration data, receiving reports from different suppliers, paying multiple subscription fees... Complicated!

At Soft dB, we believe in simplicity, which is why we offer both.

Our R&D team works closely with our field experts to design and manufacture some of the industry's most advanced intelligent vibration sensors, such as SGS ultra-precise geophones and SVS MEMS sensors.

|

Our aim is to provide our clients with the simplicity of a precise solution that can support multiple requirements of each vibratory project. It shouldn’t have to be complicated. With Soft dB solutions, you can be certain that you're measuring the right data, with the right instruments, at the right time - so that you can concentrate on your other activities with peace of mind. |

Need a Quote for Our Smart Triaxial Geophone or Advice on Vibration Monitoring?

With Soft dB, you will have all your bases covered when it comes to vibration and acoustics, in any application you require. You're assured of measuring the right data, with the best instruments, using cutting-edge technology that meets the real needs in the field, and you benefit from world-renowned vibration monitoring expertise. Monitor your vibration and noise levels like never before.

Contact our vibration monitoring experts